In a groundbreaking development that reads like science fiction, researchers have successfully engineered silkworms to produce spider silk proteins through advanced genetic modification, resulting in a material with strength properties surpassing that of specialty steel. This remarkable achievement represents not just a leap in materials science but a fundamental shift in how we approach sustainable high-performance material production.

The quest for stronger, lighter, and more sustainable materials has long driven scientific innovation. For decades, materials scientists have looked to nature for inspiration, particularly to spider silk, which possesses an extraordinary combination of strength, flexibility, and lightness. Spider silk has a tensile strength comparable to high-grade steel while being significantly less dense and remarkably elastic. However, farming spiders for their silk has proven commercially unviable due to their territorial nature and low yield.

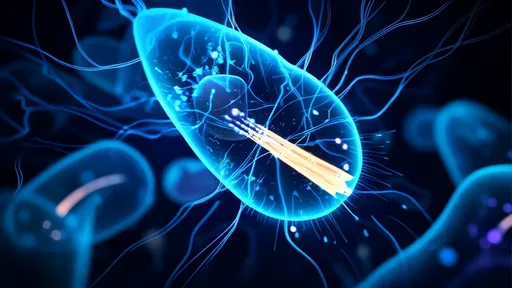

Enter the humble silkworm - nature's most efficient silk producer. For thousands of years, humans have domesticated silkworms for their luxurious filament, but natural silk, while valuable for textiles, lacks the mechanical properties of spider silk. The research breakthrough came when scientists successfully inserted genes responsible for spider silk protein production into silkworms, creating transgenic organisms that combine the production efficiency of silkworms with the material properties of spider silk.

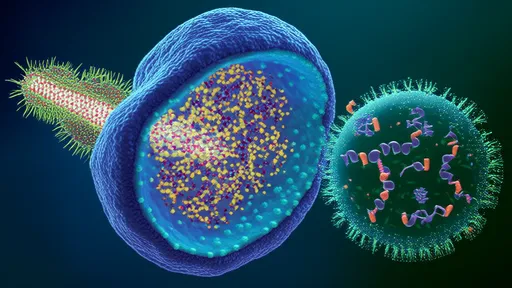

The genetic engineering process represents a marvel of modern biotechnology. Researchers identified and isolated the specific genes in spiders that code for the strongest silk proteins, particularly those from the golden orb-weaver spider, known for producing some of nature's toughest silk. Using advanced CRISPR-Cas9 gene-editing techniques, scientists then precisely inserted these genes into silkworm embryos at locations that would ensure the spider silk proteins would be properly expressed and integrated into the silkworm's natural silk production system.

What makes this achievement particularly remarkable is that the modified silkworms not only produce the spider silk proteins but properly assemble them into fibers with the same complex hierarchical structure that gives natural spider silk its exceptional properties. The resulting composite material maintains the production scalability of traditional silk while achieving mechanical properties previously only found in spider silk.

The mechanical testing results have astonished materials scientists. The engineered silk demonstrates a tensile strength of approximately 2.0 GPa, significantly exceeding that of specialty steel alloys (which typically range from 0.5 to 1.5 GPa) while being only one-sixth the density. This gives the material a specific strength (strength-to-density ratio) nearly ten times greater than steel. Additionally, the engineered silk maintains the impressive elasticity of natural spider silk, able to stretch up to 40% of its length without breaking, compared to steel's typical 0.2-2% elongation at break.

The applications for this super-strong biological material are vast and transformative. In the medical field, it could revolutionize surgical sutures, tissue engineering scaffolds, and artificial ligaments. Its biocompatibility and gradual biodegradability make it ideal for implants that need to provide temporary structural support as the body heals. The material's strength and flexibility could lead to better prosthetic devices and improved wound closure systems.

In aerospace and automotive industries, the material's exceptional strength-to-weight ratio could lead to lighter, more fuel-efficient vehicles and aircraft. Composites reinforced with this engineered silk could replace carbon fiber in many applications while being more sustainable and environmentally friendly. The material's ability to absorb energy makes it promising for impact-resistant structures and safety equipment.

The military and protective equipment sectors are particularly interested in this development. The material could lead to lighter, more flexible body armor that provides better protection than current Kevlar-based systems. Its potential for energy absorption could improve helmet technology, reducing traumatic brain injuries among soldiers and athletes alike. The material's thermal stability and strength retention across a wide temperature range make it suitable for various extreme environment applications.

Perhaps most significantly, this engineered silk represents a sustainable alternative to many synthetic high-performance materials. Traditional steel production is energy-intensive and generates significant carbon emissions. Synthetic polymers often derive from petroleum and present environmental persistence problems. In contrast, this bio-based material production relies on silkworms feeding on mulberry leaves, a renewable resource, with the entire process having a much lower environmental footprint.

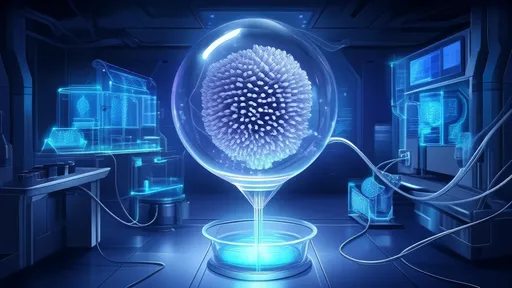

The production scalability appears promising. Silkworms have been cultivated for silk production for millennia, with established infrastructure and expertise worldwide. A single silkworm cocoon can yield up to 1,500 meters of continuous filament, and the insects can be raised efficiently in controlled environments. The genetic modification doesn't affect the worms' viability or reproduction, meaning production could be scaled using existing sericulture frameworks.

Despite the excitement, researchers caution that commercial production still faces challenges. Ensuring consistent quality and properties across production batches requires further refinement. The extraction and processing methods need optimization to handle the stronger fibers without damaging them. Regulatory approval for various applications, particularly medical uses, will require extensive testing and documentation.

The research teams are now working on further enhancements, including modifying the silk proteins to incorporate additional functional properties such as conductivity, antimicrobial activity, or specific biological recognition sites. Some groups are experimenting with altering the amino acid sequences to create variants with even greater strength or specialized properties for particular applications.

This breakthrough also opens new possibilities for biological manufacturing more broadly. The success of engineering silkworms to produce foreign proteins suggests that other organisms could be similarly modified to produce valuable materials, potentially leading to a new era of bio-based manufacturing where everything from construction materials to electronics components could be grown rather than manufactured through energy-intensive processes.

The ethical considerations are being carefully addressed. The genetic modifications are designed to not cause harm to the silkworms, and containment protocols ensure that modified organisms do not enter the natural ecosystem. The research teams are working with bioethicists to establish guidelines for this new field of biological materials production.

As development continues, partnerships are forming between research institutions and industrial partners to accelerate commercialization. Several startups have already emerged focused specifically on developing applications for this engineered silk, attracting significant investment from venture capital firms and established materials companies looking to diversify into sustainable alternatives.

The scientific community recognizes this achievement as a milestone in convergent research, where genetics, materials science, and engineering combine to create solutions that no single discipline could achieve alone. The successful marriage of spider silk genes with silkworm production capabilities demonstrates the power of interdisciplinary approaches to solving complex material challenges.

Looking forward, researchers believe this is just the beginning. The same principles could be applied to enhance other natural materials or create entirely new biological materials with properties not found in nature. Some envision a future where designed proteins enable materials that self-assemble, self-repair, or adapt to environmental conditions - all produced sustainably through biological systems.

This spider-silk supermaterial from genetically modified silkworms stands as a testament to human ingenuity's ability to learn from and improve upon nature's designs. It offers a vision of a future where high-performance materials don't come from smelters or chemical plants but from living organisms working in harmony with their environment, potentially transforming everything from medicine to manufacturing while reducing our ecological footprint.

By /Aug 18, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 18, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 27, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025